A GaN technology breakthrough claimed for hard switching

- ICDesign

- 2023-09-23 23:01:21

A new gallium nitride (GaN) solution claims to take the technology well over its current limitations of 100 kHz to facilitate hard switching at high voltages for motor drive systems serving applications such as HVAC and robotics. Two new modules from QPT have employed an IP that enables GaN transistors in high-voltage, hard-switching applications to run at frequencies of up to 20 MHz while providing ultrafast switching in the 1-2 ns range as opposed to 20-50 ns range for GaN when constrained to under 100 kHz to avoid heating and electromagnetic compatibility (EMC) issues.

Unlike silicon carbide (SiC), which cannot run at converter speeds faster than 100 kHz without switching losses becoming unacceptable, GaN can switch fast at 1-2 ns speeds and support high converter speeds of 10’s of MHz. But the exceptionally difficult EMC and thermal issues must be resolved to achieve this inherent GaN merit.

The current solutions throttle back to sub-100 kHz frequencies to avoid overheating and RF interference. As a result, GaN’s performance is similar to SiC as it cannot run at high switching frequencies to deliver power savings. “There are massive EMC issues, and they are expensive to fix,” said Rob Gwynne, QPT’s founder and CEO.

However, the importance of GaN technology primarily comes from its ability to operate at ultra-high frequencies for switching on and off. Otherwise, during the switching time, when the transistor is neither on nor off, it dissipates huge amounts of power, leading to energy losses and overheating issues.

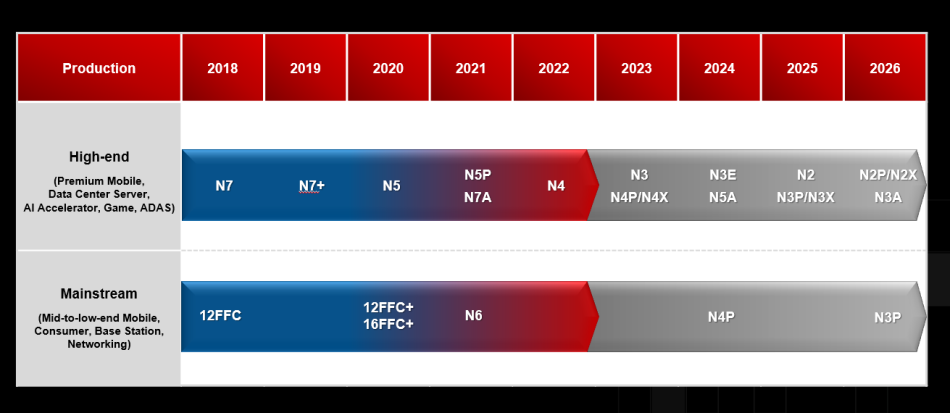

Figure 1 The three curves show losses of SiC and GaN devices at 500 kHz (above), losses at 1 MHz (middle), and GaN losses at 2 MHz while running hard switching (below). Source: QPT

“When dv/dt is greater than current isolated gate drivers can tolerate, your system will self-destruct, or you must limit dv/dt, thereby wasting power,” Gwynne added. “That’s how you end up with RF/microwave power routing/matching issues with interconnect.” Consequently, power design engineers must change the filter and decoupling components to operate at microwave frequencies.

Next, they must employ common mode and differential mode complex microwave filters to resolve conducted emissions issues. “We have solved the incredibly complex problems of EMC, thermal control, and RF/microwave interconnect,” Gwynne said. QPT’s solution enables GaN transistors to run at their full potential of up to 20 MHz with nanosecond switching and deliver better operational precision without overheating or RF interference issues.

Key application: Motor drive

The key application benefitting from GaN’s ultra-high frequencies for switching on and off will be control electronics for motor drives. Here, high efficiency can play a vital role in saving energy via speed controls for motors. “Electric motors account for 45% of global electricity usage and our technology can make them more efficient and that means less carbon dioxide emissions which helps combat climate changes,” said Gwynne.

This is how it all works. Variable frequency drives (VFDs) in motor control operate by chopping the incoming power to create a frequency that can be changed to adjust the speed of the motor, and energy is lost every time chopping occurs. It’s important to note that the common perception among manufacturers is that this energy loss is minimal. However, when manufacturers quote an efficiency of 97%, it’s at full speed. So, when the speed drops, the efficiency drops significantly, a fact generally ignored by manufacturers.

Figure 2 Here is a comparison between a typical VFD efficiency dropping off dramatically as motor speed drops (below) and efficient motor control enabled by higher frequency GAN technology (above). Source: QPT

To reduce energy wastage and boost efficiency, the chopping needs to be fast, transitioning from off to on or on to off as quickly as possible. Therefore, during the switching time, when the transistor is neither on nor off, energy dissipation accounting for most of the energy losses can be contained. It wastes very little energy chopping the DC into variable frequency AC to drive the motor across the complete range of different speeds.

Two modules and a reference design

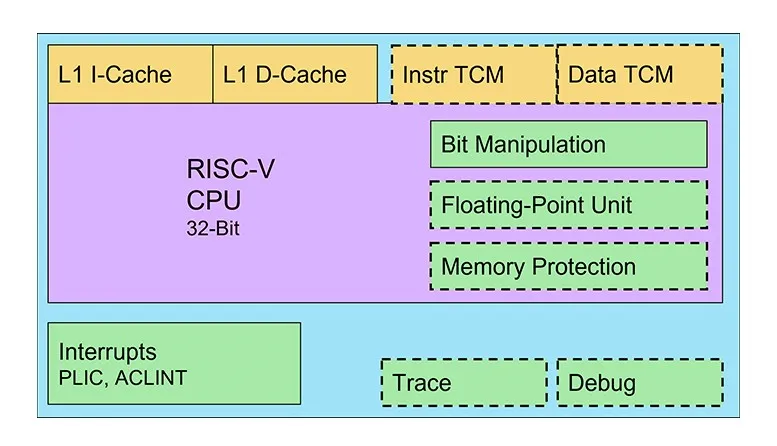

The first module, qGaN, is built around a 650-V GaN transistor and the company’s qDrive low jitter isolated GaN transistor gate drive. The second module, qSensor, provides the sensing and control that enables the GaN to be driven at super high frequencies.

Figure 3 The qGaN module can handle 15-A RMS current while driving 380-V three-phase motors. Source: QPT

To provide design support for these modules, QPT has developed the WisperGaN construction system that includes a reference design to show engineers how the modules can be assembled in a Faraday cage so that there are no heating or RF issues. According to the company, it demonstrates up to 80% reduction in power usage compared to existing solutions that operate at much lower frequencies.

QPT, based in Cambridge, UK was founded in 2020 as an independent power electronics company.

Related Content

SiC and GaN: A Tale of Two Semiconductors“Navitas Presents” to focus on GaN at CES 2023GaN’s applications roadmap spotted at CES 2023The diverging worlds of SiC and GaN semiconductorsIntegrated GaN Half-Bridge Delivers MHz PerformanceA GaN technology breakthrough claimed for hard switching由Voice of the EngineerICDesignColumn releasethank you for your recognition of Voice of the Engineer and for our original works As well as the favor of the article, you are very welcome to share it on your personal website or circle of friends, but please indicate the source of the article when reprinting it.“A GaN technology breakthrough claimed for hard switching”